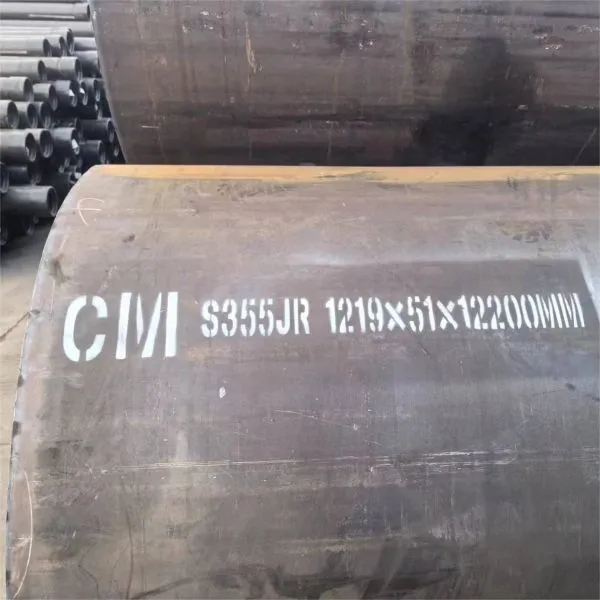

S355JR Large Diameter 51MM Thickness LSAW Pipe Manufacturers

LSAW pipe advantage

1. High strength: Due to the submerged arc welding process, LSAW pipes have higher welding quality and good strength and toughness.

2. Suitable for large-diameter pipes: LSAW pipes are suitable for the production of large-diameter pipes and can meet the needs of transporting large-flow liquids or gases.

3. Suitable for long-distance transportation: Since the welding seam of LSAW pipeline is a long weld, it is suitable for long-distance transportation, which can reduce pipeline connection points and reduce the risk of leakage.

Outside Diameter: Φ508mm- 1219mm

Wall Thickness: 6.0-50MM

Product Details

LSAW pipe advantage

1. High strength: Due to the submerged arc welding process, LSAW pipes have higher welding quality and good strength and toughness.

2. Suitable for large-diameter pipes: LSAW pipes are suitable for the production of large-diameter pipes and can meet the needs of transporting large-flow liquids or gases.

3. Suitable for long-distance transportation: Since the welding seam of LSAW pipeline is a long weld, it is suitable for long-distance transportation, which can reduce pipeline connection points and reduce the risk of leakage.

Related Parameters

|

LSAW Steel Pipe (Longitudinally Submerged Arc Welding Pipe) , DSAW Steel Pipe |

|

|

Straight Seam Submerged Arc Welded Steel Pipe |

|

|

Outside Diameter |

Φ508mm- 1219mm |

|

Wall Thickness |

6.0-51mm |

|

Quality Standards |

API, DNV, ISO, DEP, EN, ASTM, DIN, BS, JIS, GB, CSA |

|

Length |

9-12.3m (30'- 40') |

|

Grades |

API 5L A-X90,GB/T9711 L190-L625 |

|

Packing |

Industry standard packaging or according to client's requirement |

Tests of LSAW steel pipe

● Chemical Component Analysis

● Mechanical Properties - Elongation, Yield Strength, Ultimate Tensile Strength

● Technical Properties - DWT Test, Impact Test, Blow Test, Flattening Test

● X-ray Test

● Exterior Size Inspection

● Hydrostatic Test

● UT Test

Product Details